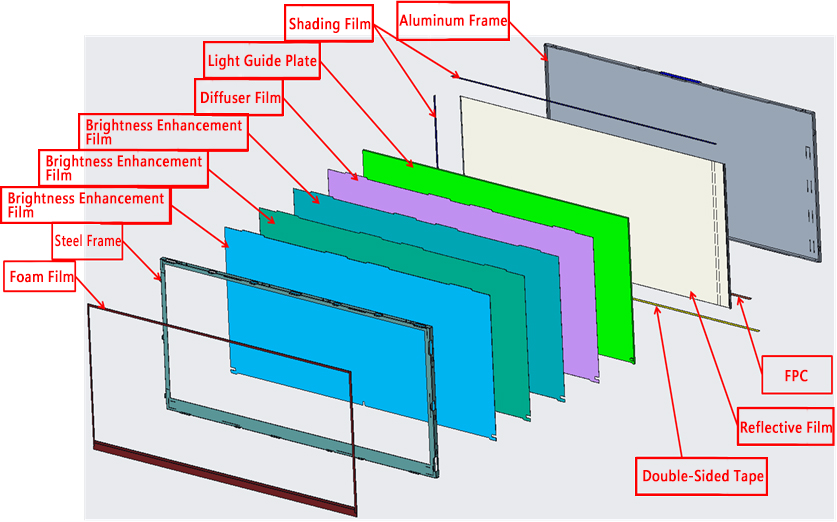

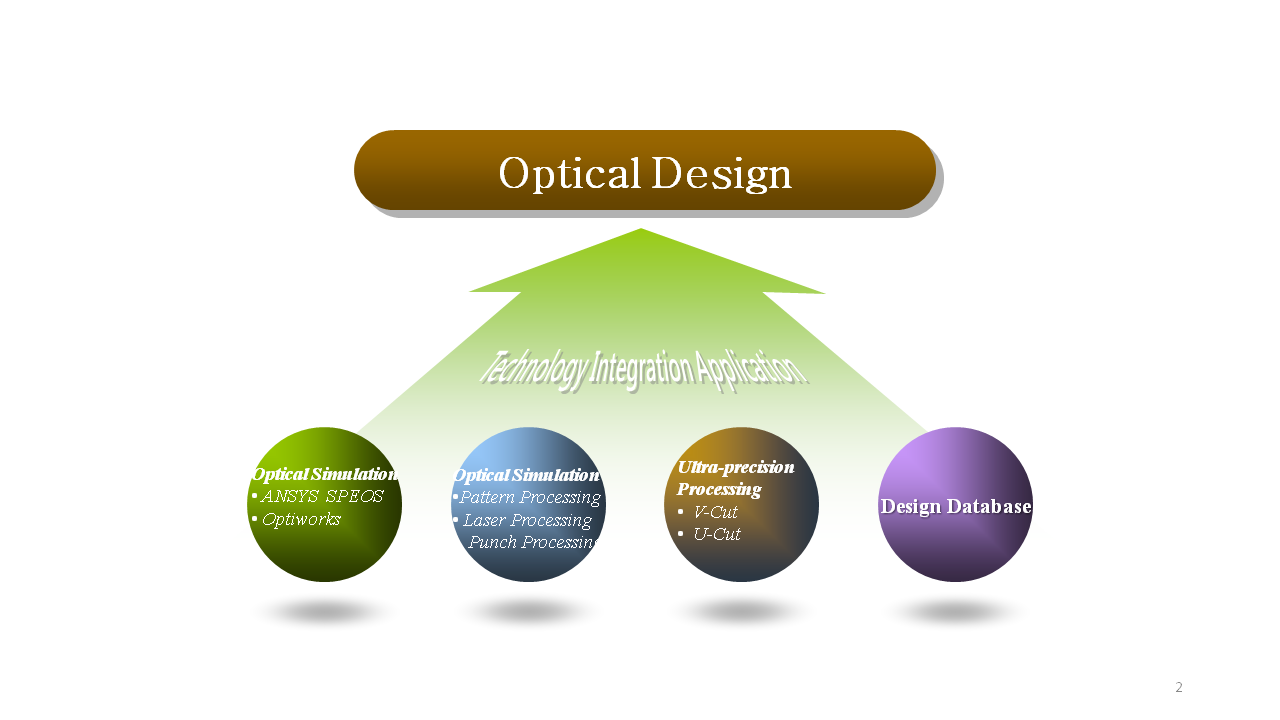

Shian Yih has collaborated with domestic and overseas academic and research institutions in numerous projects to develop innovative technologies, successfully introduced computer optical simulation systems, and introduced advanced optical microstructure processing equipment and V-groove cutting texture to achieve modules with high brightness and high uniformity. Shian Yih is actively developing various backlight module related materials (such as optical films, adhesives, coating, thermal interface material, etc.) and shortening the assembly cycle to achieve the best production efficiency.

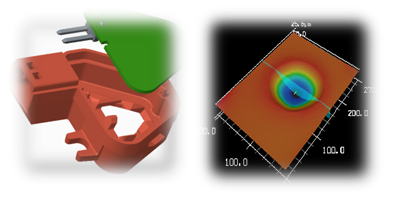

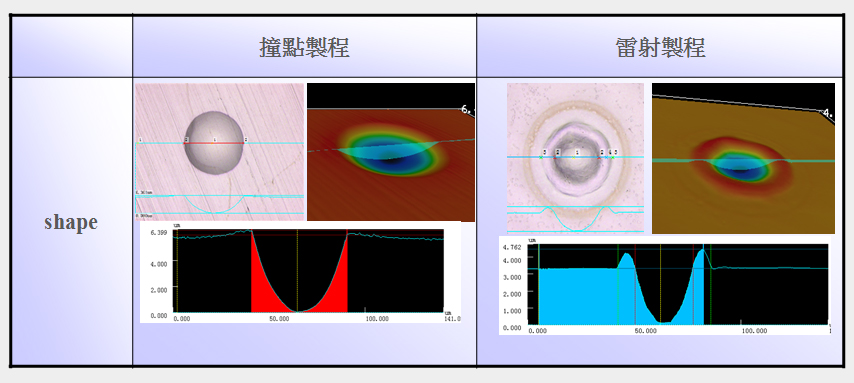

New technology – Optical microstructure

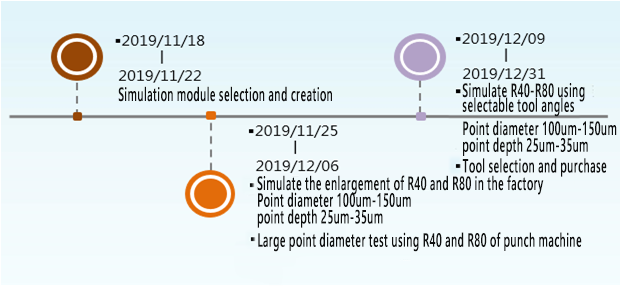

Deep punch

- Bottom Side of LGP

- Ø=80 µm ~120 µm

- Depth=20~35µm

- LGP T >=1.0 mm

Optical brightness enhancement – Punch point enlargement simulation and trial production scheduling

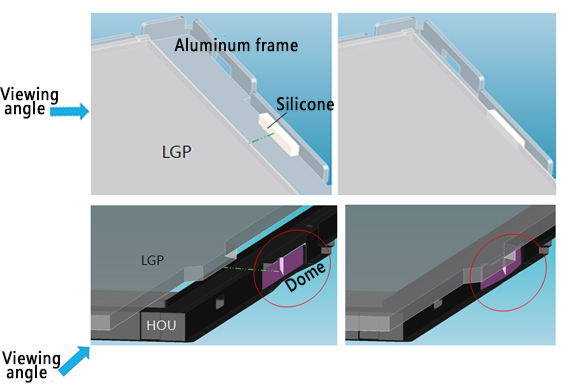

New Technology – Fixed LGP: Use HOU dome instead of silicone

- Meets automated machine assembly and production

- Eliminate silicone to reduce material costs

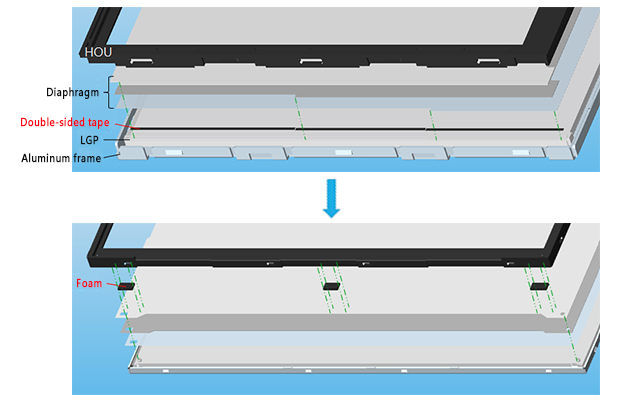

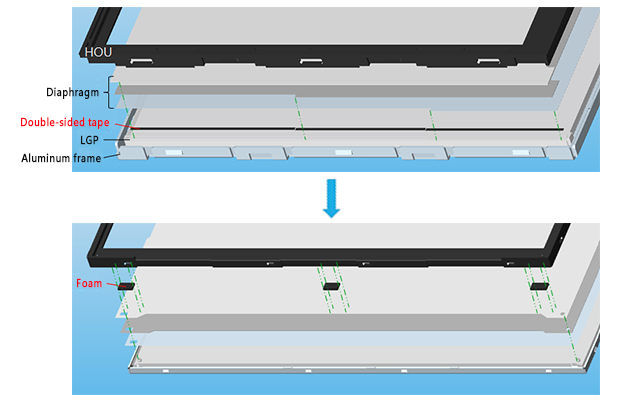

New Technology – Fixed diaphragm: Use foam instead of double-sided tape

- Meets automated machine assembly and production

- Reduces the risk of film deformation at high temperatures

New Technology – Narrow bezel control expansion and contraction ratio: Middle positioning basis

- Meets automated machine assembly and production

- Reduces the risk of film deformation at high temperatures

Optical Design

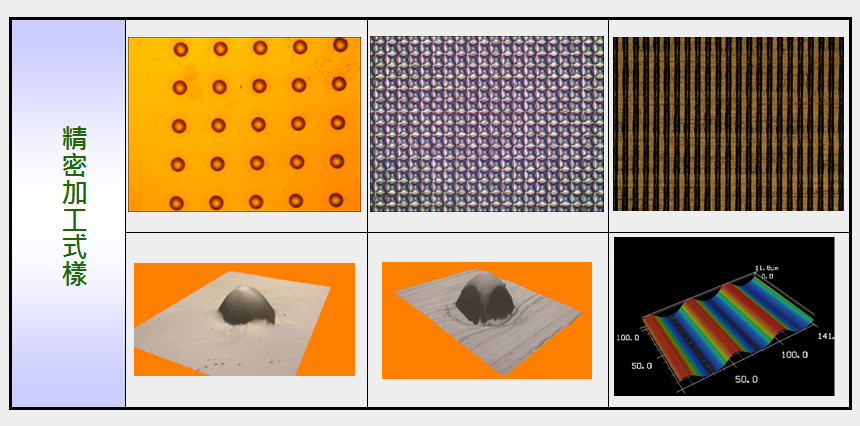

Microstructure On the Light Guide

In-house Microstructure Processing

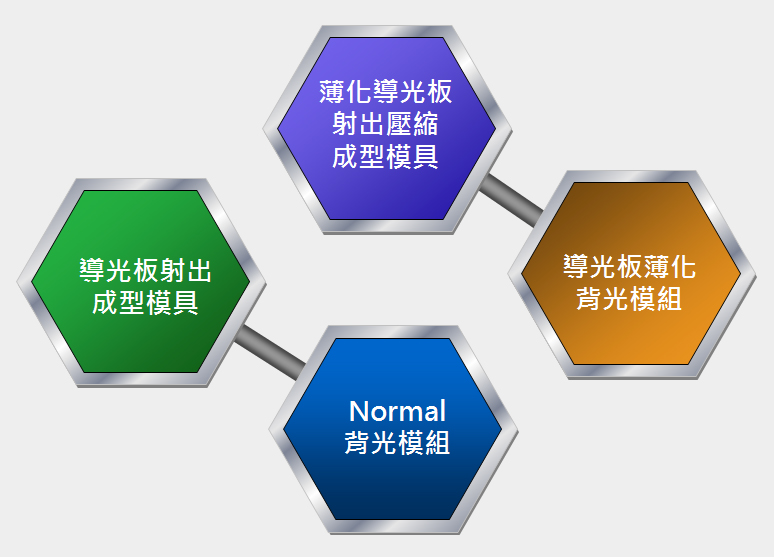

Tooling Design

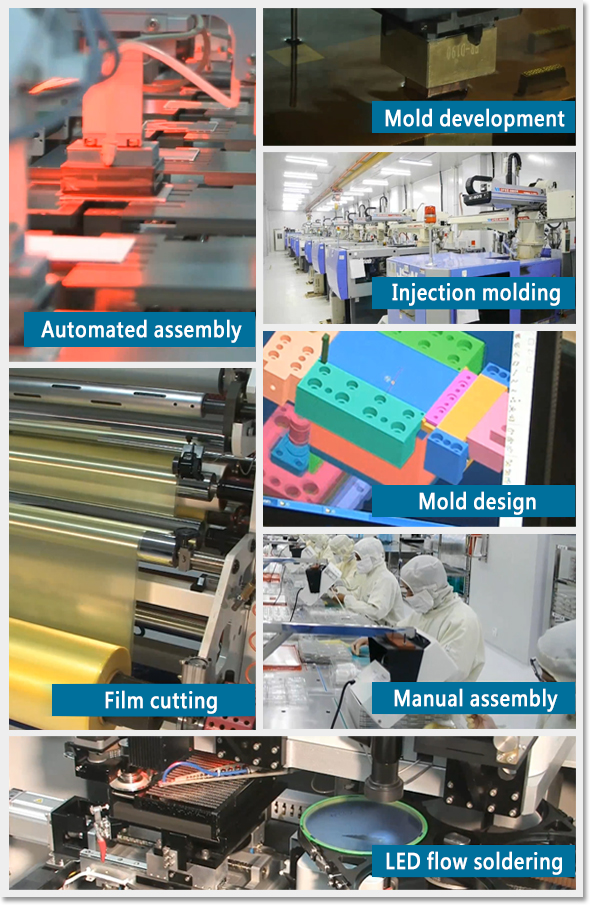

The Company’s main product is backlight modules, and the process from module design -> mold design and manufacturing -> plastic injection molding -> films cutting -> tapes cutting -> SMT -> potting/dispensing/coating -> finished product assembly -> packaging and shipping are all carried out in the factory. In order to achieve the highest production efficiency, we import the most advanced machinery and equipment from overseas, such as precision injection molding machines, automatic processing equipment, SMT machines, and regularly replace old equipment with new ones. The production technology department also maintains the production line in the most efficient production mode through continuous process improvement.

At the same time, in order to meet the standards of pollution-free manufacturing process for backlight modules, the first clean room was established in 2001. All production lines meet cleanliness class requirements.